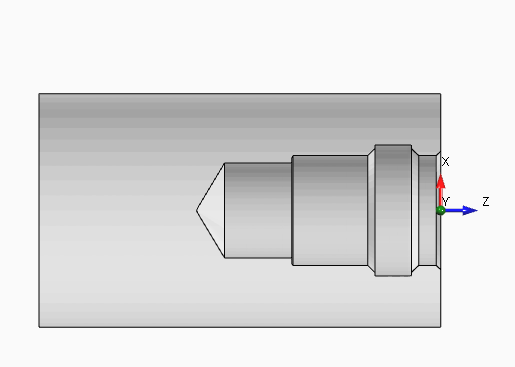

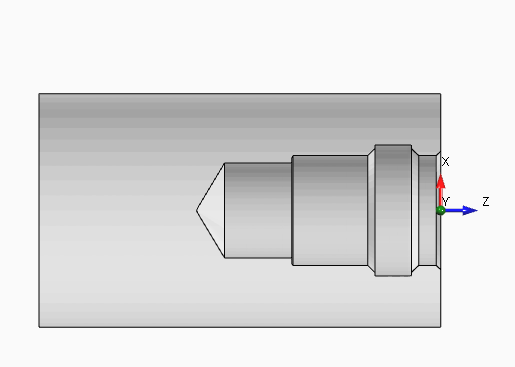

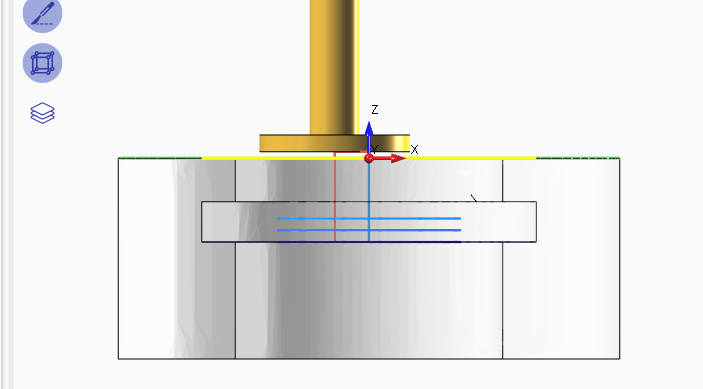

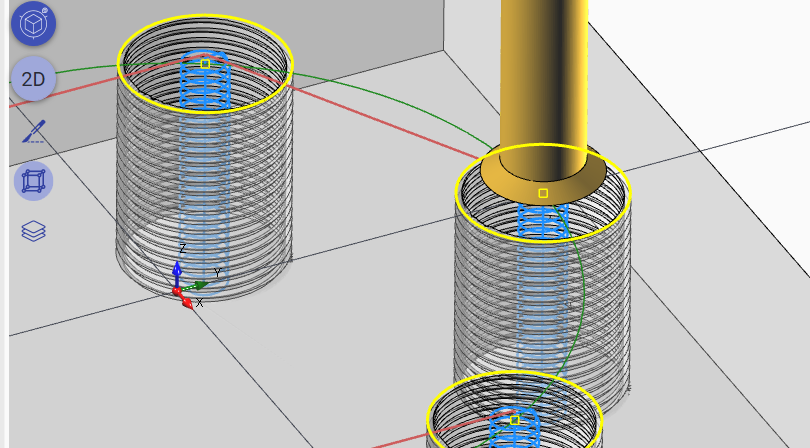

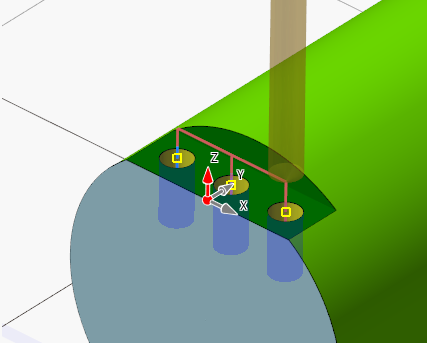

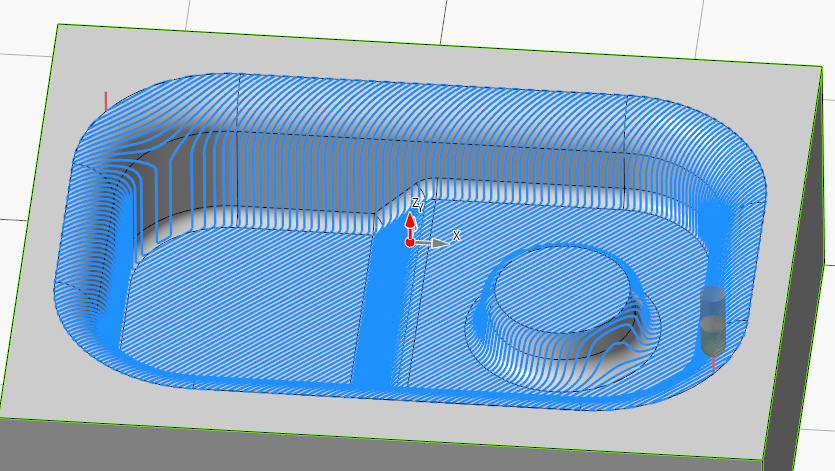

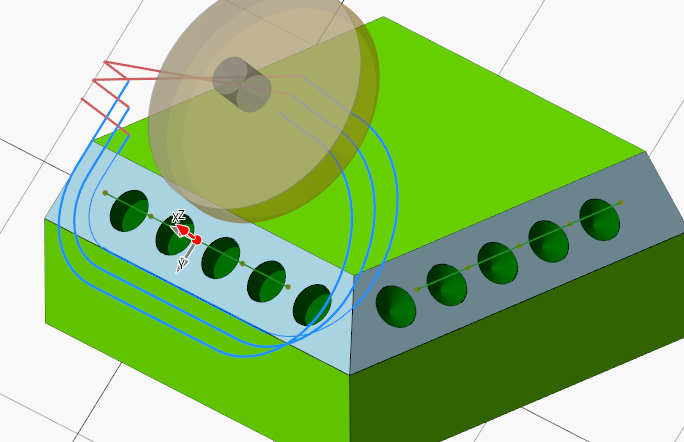

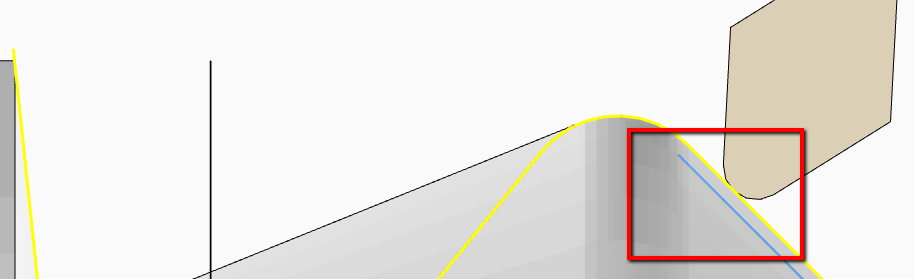

3D Stock modelling

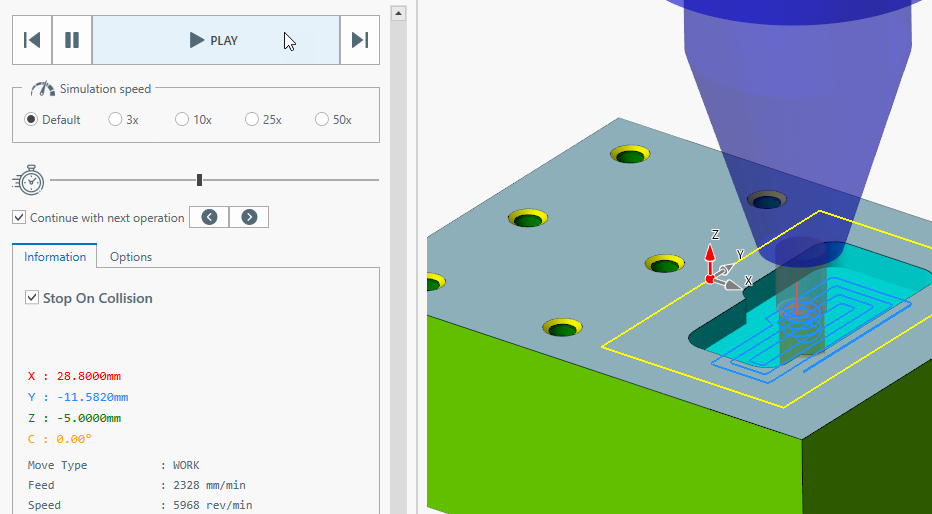

The 3D rappresentation is the effective result of all toolpath movements applied to the stock model.

Ecam is designed to speed up the g-code generation for simple part.

In short, if most of your production consist in simple component, and you feel common cad/cam are an overkill for your jobs, give a try to eCam, probably it will fit your needs.

ECam combines features of CAD/CAM system with typical features of conversational programming.

Take a look at quickstart

The 3D rappresentation is the effective result of all toolpath movements applied to the stock model.

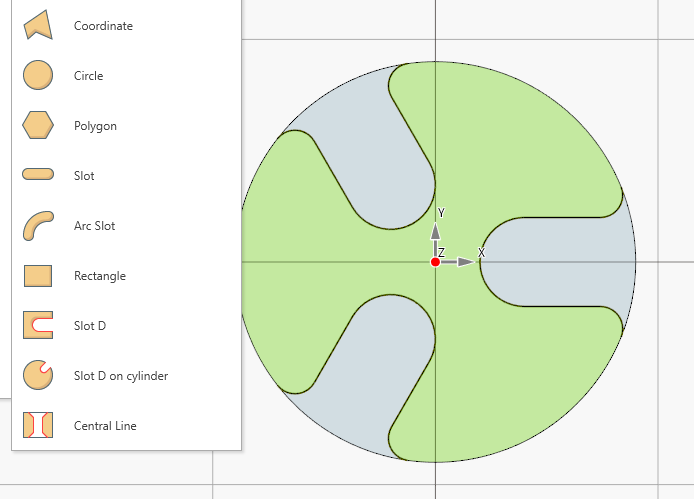

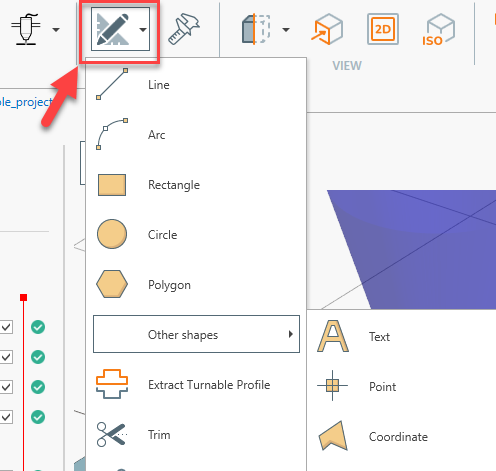

Is possible define the most common and recurrent geometry profile by just insert some parameters.

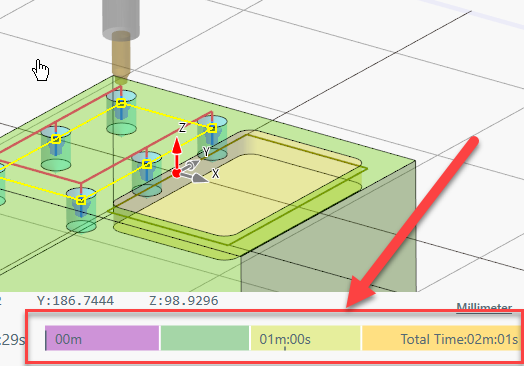

See at glance , what operations are taking most of the machining time.

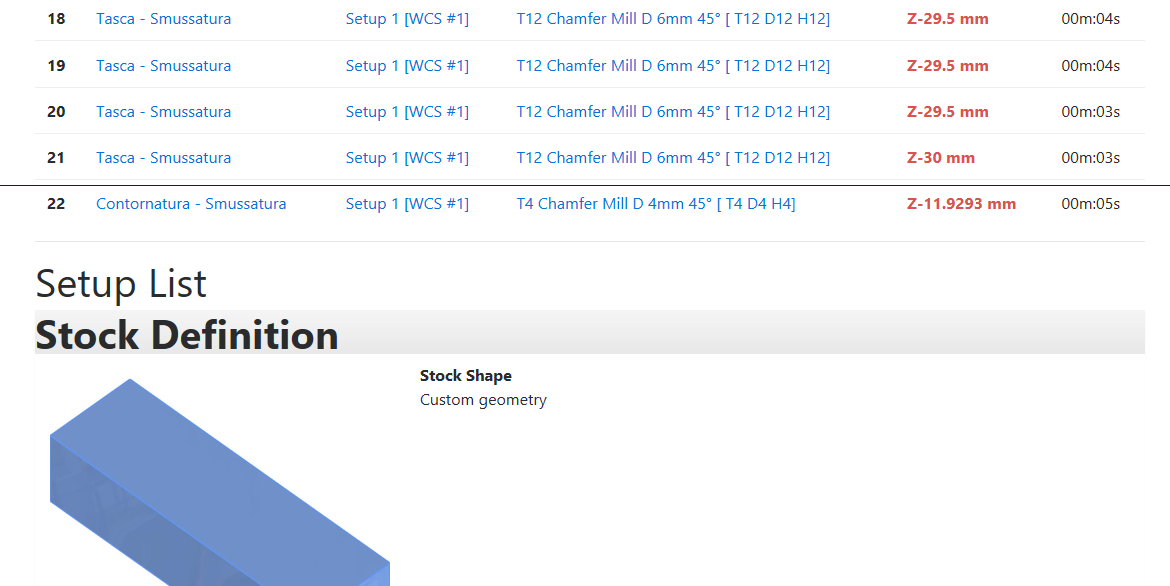

Create documentation for the shop floor with a click. Containing all the information to setup.

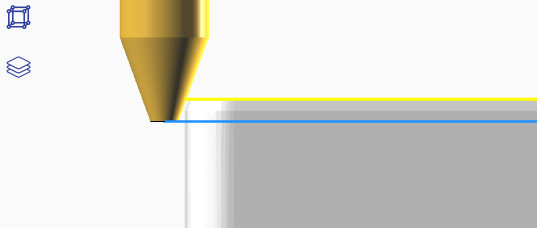

Control the animation speed. It shows the current position and the current values of feed and speed.

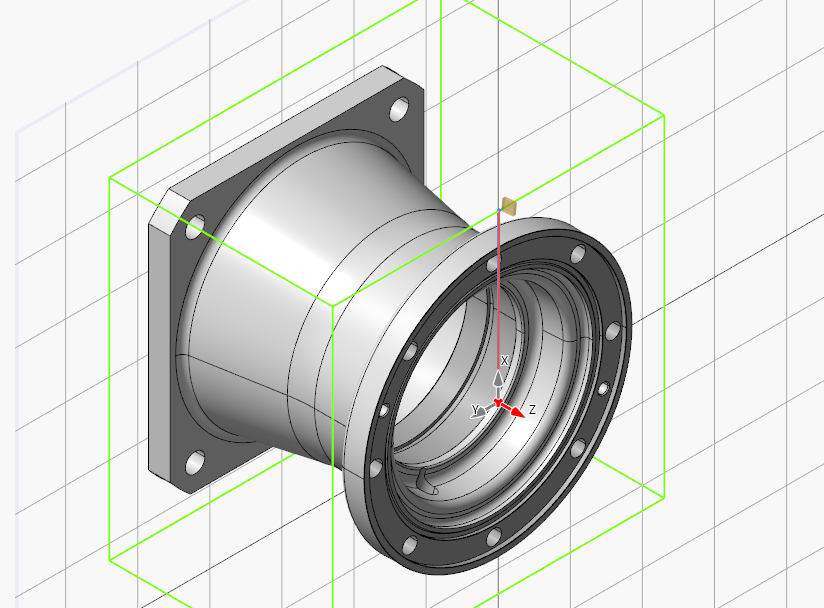

Import existing 2D geometries and 3D models from several format files.

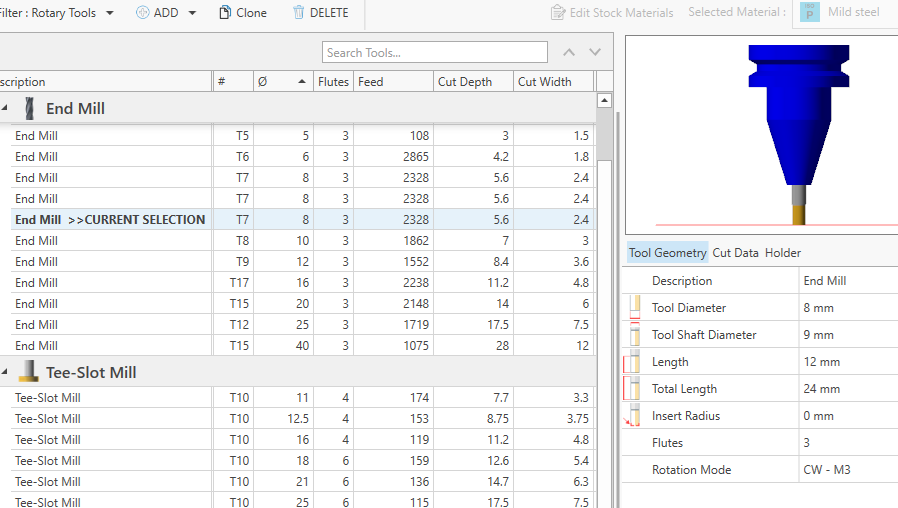

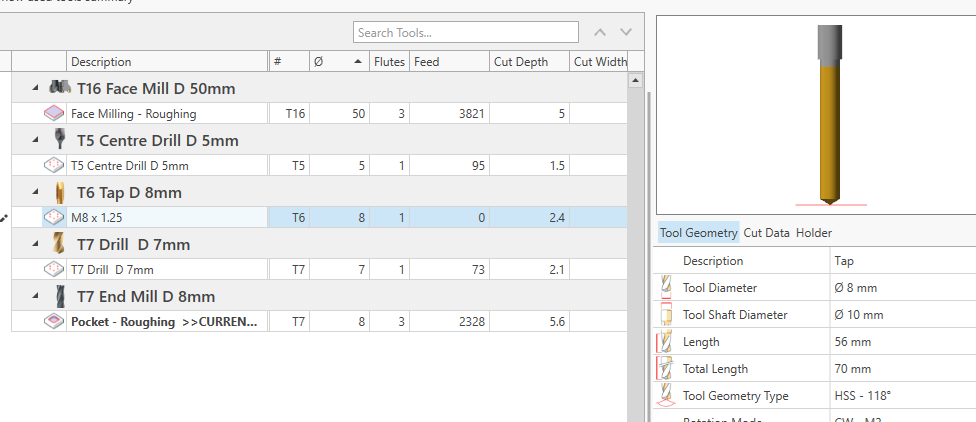

A tool can habe multiple set of cutting data, one set for each stock raw material.

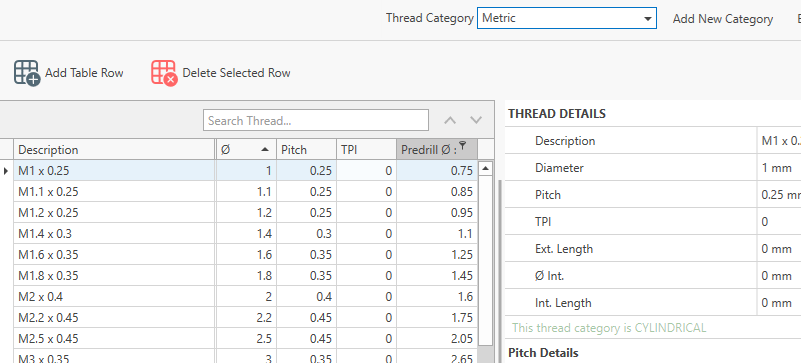

ECam comes with an internal thread database , covering most of common thread family.

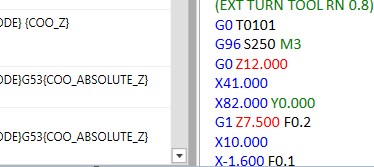

use a simple system to post process the toolpath into g-code , no coding experience is required.

If the linked geometry is changed, all the child operations are updated consequently.

Basic set of cad tools. Useful to adjust imported cad geometries or to draw simple shapes.

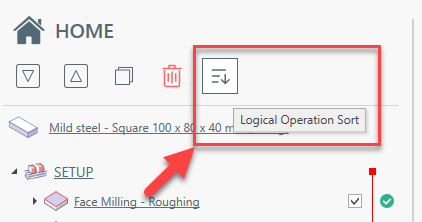

The operations are sorted in a logical way, by default. Change this sorting with drag & drop.

Click on this button to get a fast overview of all used tools in current project.

A "must have" feature if you need to work mild steel or inox material.

Create slot-t safely with just a couple of parameter.

Select the thread type from dropdown button. Select compatible thread mill.

Engrave 2D geometries or plain text. Select single line or True Type font. Linear or circular disposition.

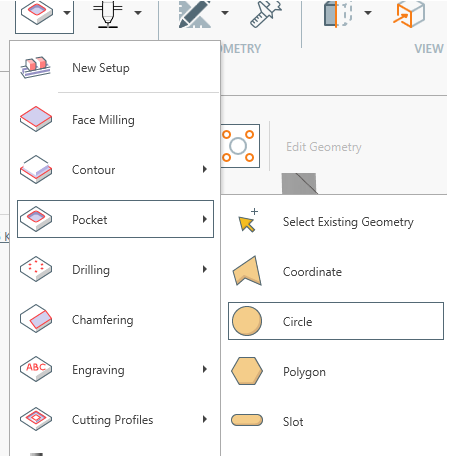

Face milling, external contouring, pocketing chamfering, cut operation, side milling

Active CHAMFERING operation and set chamfer depth. No other setting needed.

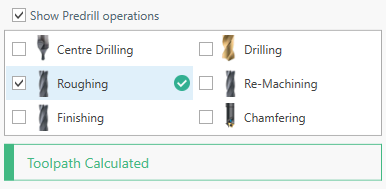

Center Drill, Drill, Reamering, Chamfering Tapping, Counterbore

Process axis y machining operations

Basic surface roughing and finishing operation available.

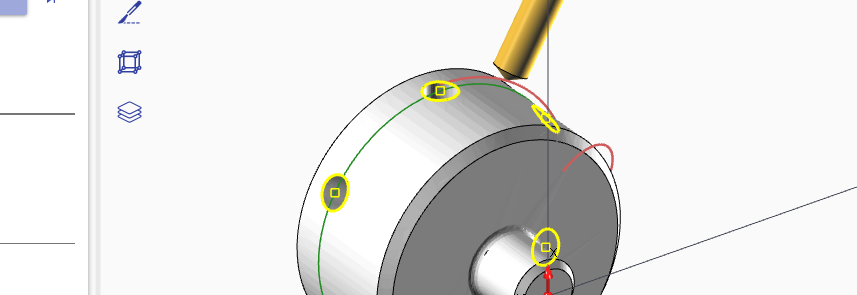

With the tool orientation feature is possible works with 3+1 or 3+2 machines or any machine that permit to move the tool orientation.

Add a face turning operation. If needed set the front chamfer or fillet.

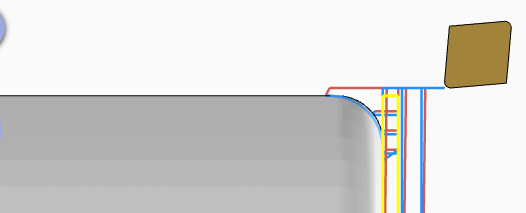

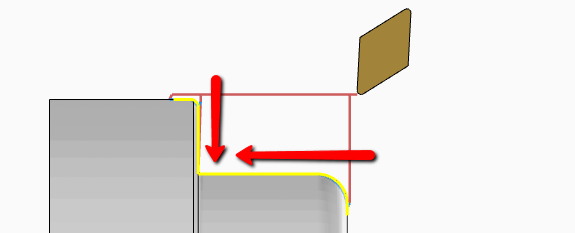

To reduce tool vibration is necessary reverse the tool direction on vertical wall.

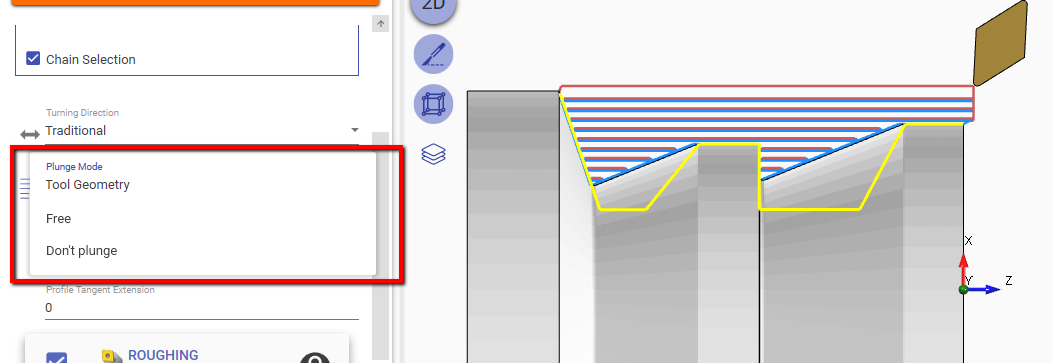

Define standard groove geometry inserting just some parameter.

Work safe, the profile is compensated with the admissible tool plunge angle.

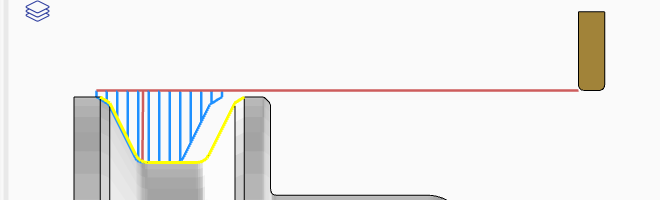

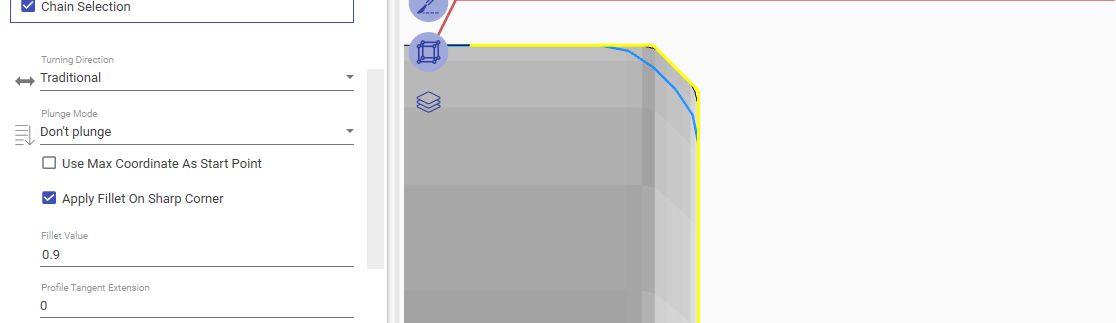

Define a minimium corner fillet radius. The profile will be adjusted automatically.

Profile is compensated also with selected tool nose radius.

MENU > MILL > NEW SETUP > Vertical mill

In this screen you can :

Press OK when done.

Once the toolpath is generated, you can :

Clear pricing system

Read the frequently asked question

This is a relatively new software . Thanks to users feedback it's becoming more stable. But new bugs can be created at every release.

Every machine can interpreter the same g-code in different way.

You need to understand clearly the meaning of the generate g-code and your responsibility check the compatibilty with your machine.

Make some dry-run test before start cutting real material, check the generate g-code step by step.

Only for: Win7 , Win8, Win10 , Win11

( X64 system only , 32 bit pc are not supported)

THE AUTHOR PROVIDES THIS SOFTWARE ''AS IS'' AND ANY EXPRESSED OR IMPLIED WARRANTIES, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE DISCLAIMED. IN NO EVENT SHALL THE AUTHOR BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL, SPECIAL, EXEMPLARY, OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED TO, PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES; LOSS OF USE, DATA, OR PROFITS; OR BUSINESS INTERRUPTION) HOWEVER CAUSED AND ON ANY THEORY OF LIABILITY, WHETHER IN CONTRACT, STRICT LIABILITY, OR TORT (INCLUDING NEGLIGENCE OR OTHERWISE) ARISING IN ANY WAY OUT OF THE USE OF THIS SOFTWARE, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.