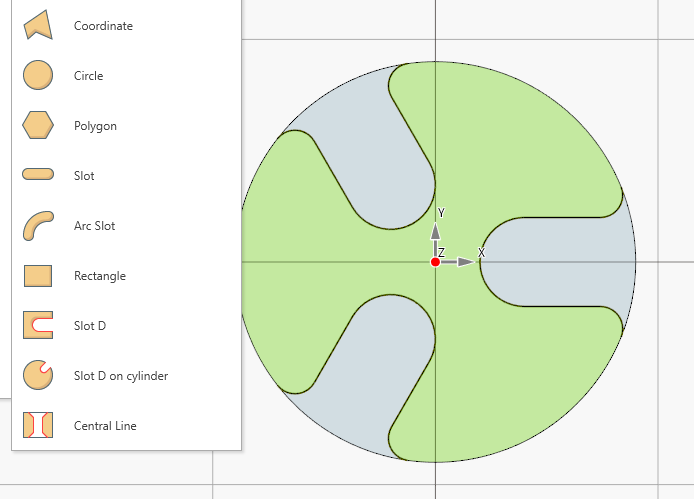

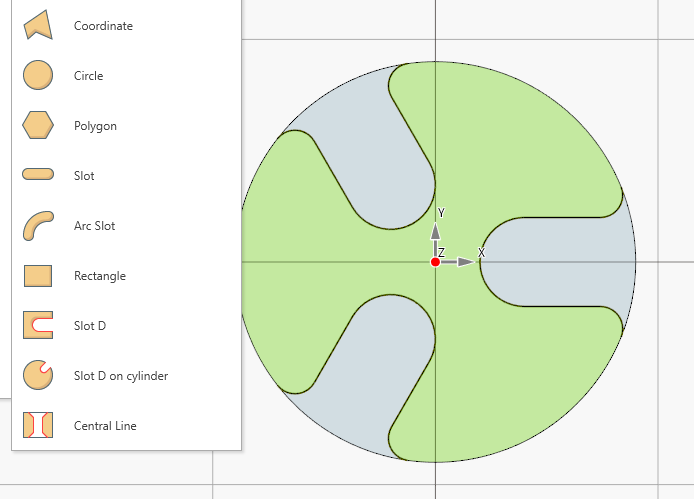

Fast Shapes

More info...Is possible define the most common and recurrent geometry profile by just insert some parameters.

Made for small shops and hobby machinists who want machine-ready G-code fast—without the complexity and cost of full CAD/CAM.

Explore some of the main capabilities of the software. For more details, visit the documentation website .

See a basic workflow example—from setup to G-code.

Compare HOBBY and PRO Edition features

| Feature | HOBBY Edition | PRO Edition |

|---|---|---|

| Price (one time payment) | €250 | €700 |

| Common features | ||

Fast Shapes

Fast ShapesIs possible define the most common and recurrent geometry profile by just insert some parameters.

|

✓ | ✓ |

|

Timeline

|

✓ | ✓ |

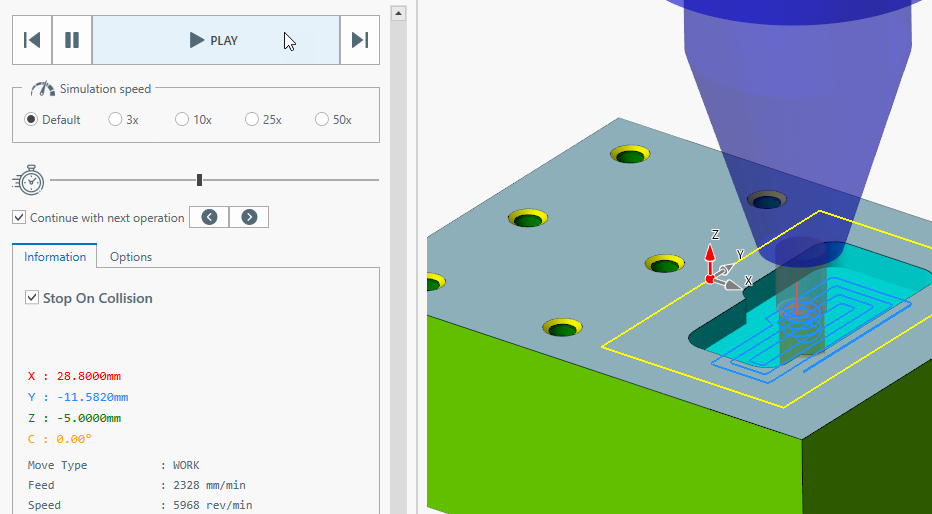

Toolpath Simulation

Toolpath SimulationControl the animation speed. It shows the current position and the current values of feed and speed.

|

✓ | ✓ |

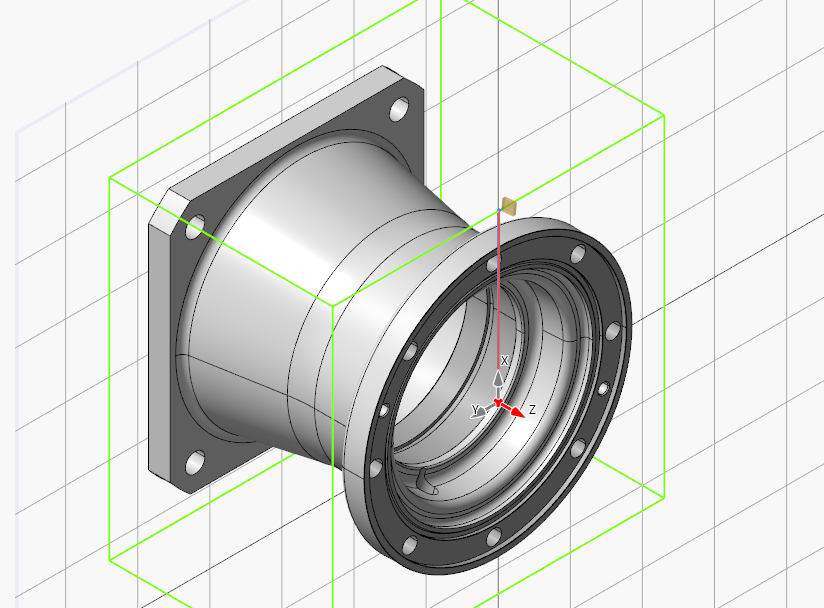

2D and 3D model import

2D and 3D model importImport existing 2D geometries and 3D models from several format files.

|

✓ | ✓ |

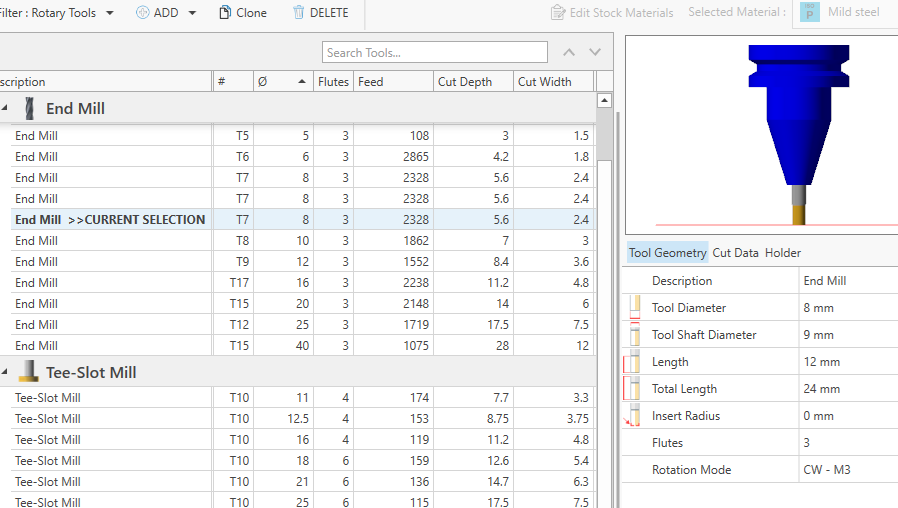

Tool store

Tool storeA tool can habe multiple set of cutting data, one set for each stock raw material.

|

✓ | ✓ |

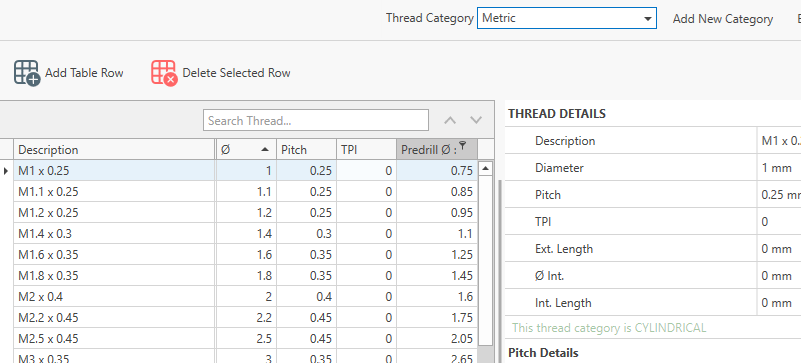

Thread Table

Thread TableECam comes with an internal thread database , covering most of common thread family.

|

✓ | ✓ |

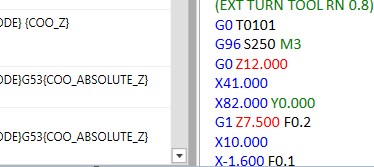

Post Processor Customization

Post Processor CustomizationCreate post processors compatible with the most common CNC controllers directly in the application. Customize the output in a simple, guided way — no programming skills required.

|

✓ | ✓ |

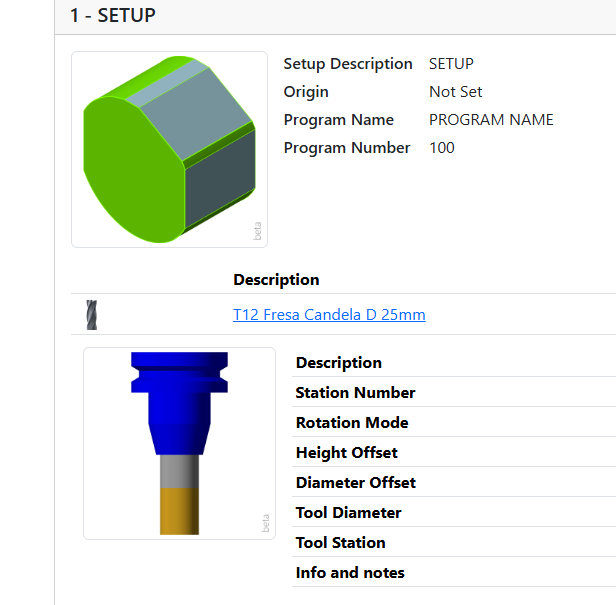

Setup Sheet

Setup SheetCreate documentation for the shop floor with a click. Containing all the information useful to machine operator to setup the machine and related tools. it's possible print the document.

|

— | ✓ |

CIMCO Edit Integration

NEW

CIMCO Edit IntegrationExport G-code together with fixtures, part/stock models, and tool data to CIMCO Edit, recreating the full machining environment for simulation. This adds an extra layer of verification and improves overall process safety.

|

— | ✓ |

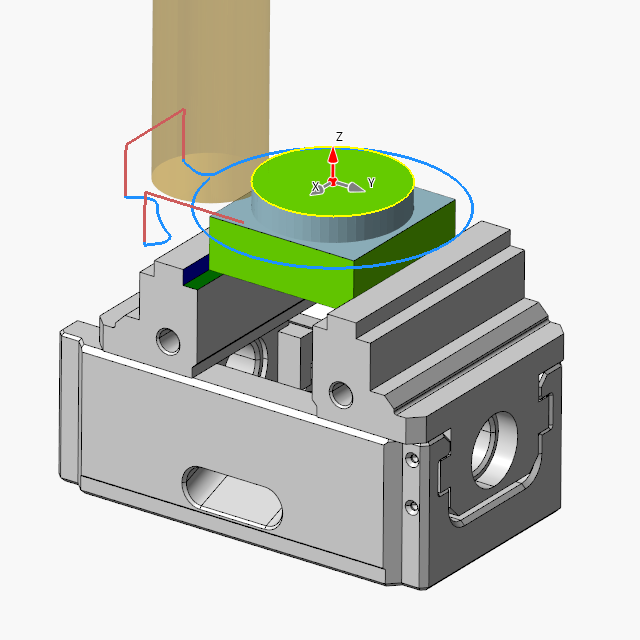

Fixture Manager

NEW

Fixture ManagerIn eCam it is possible to manage various types of fixtures, which help improve project clarity, toolpath planning, and simulation accuracy.

|

— | ✓ |

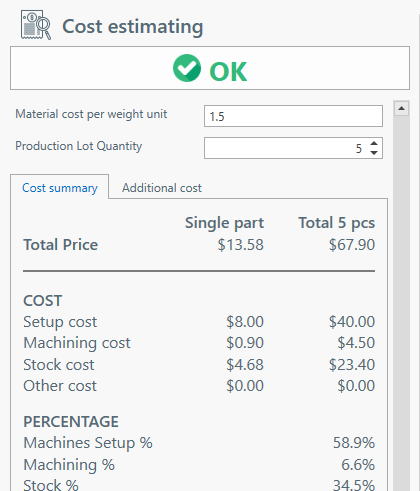

Cost estimating report

Cost estimating reportEstimate part production cost based on material and batch size. Add extra costs manually or via custom scripts for maximum flexibility.

|

— | ✓ |

| Milling module | ||

Engrave

EngraveCreate engraving toolpaths quickly for text and decorative details, with full control over depth and machining settings.

|

✓ | ✓ |

Adaptive Strategy

Adaptive StrategyA "must have" feature if you need to work mild steel or inox material.

|

— | ✓ |

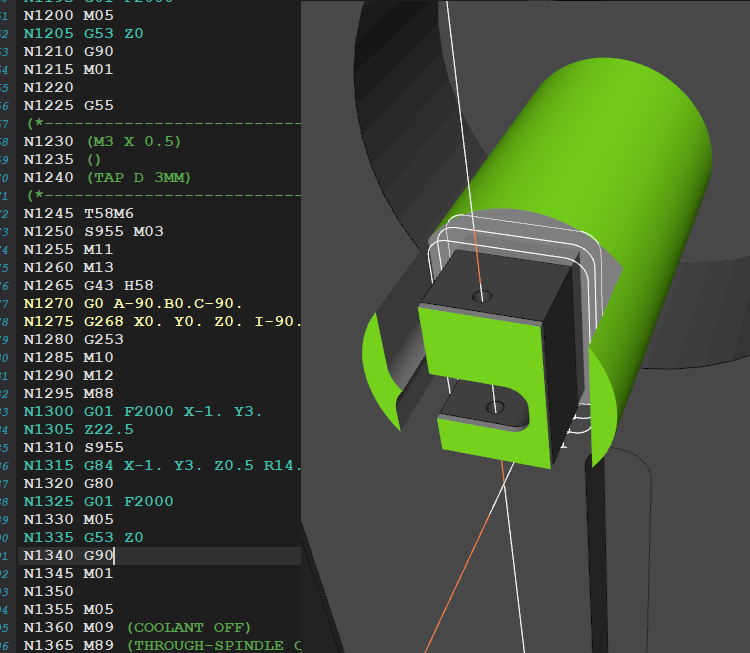

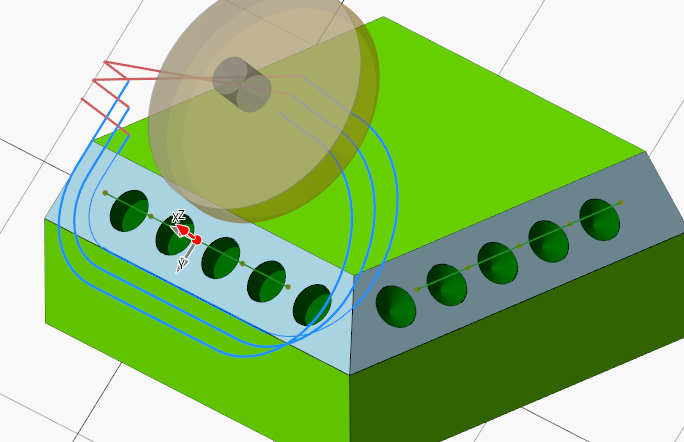

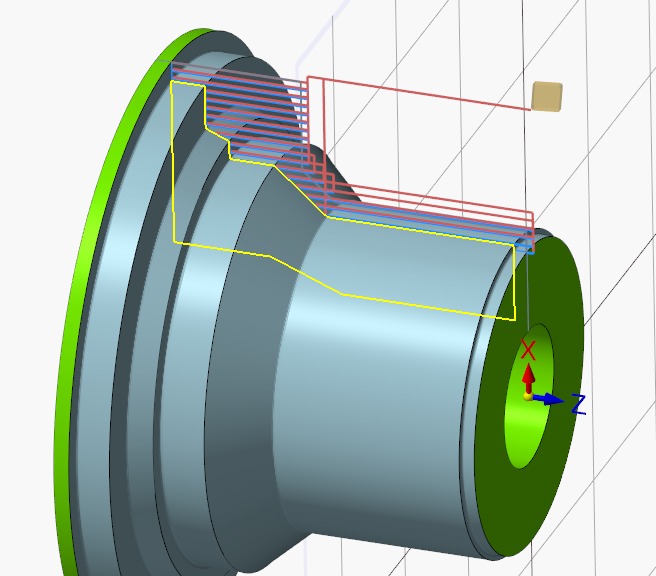

Indexed Axis support

Indexed Axis supportWith the tool orientation feature is possible works with 3+1 or 3+2 machines or any machine that permit to move the tool orientation.

|

— | ✓ |

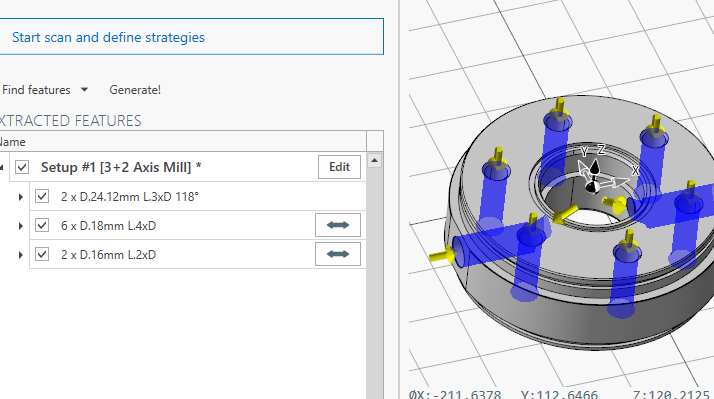

Drilling Recognition

NEW

Drilling RecognitionAutomatically create drilling operations by recognizing holes in the 3D model.

|

— | ✓ |

| Turning module | ||

Live C tools on lathe

Live C tools on lathe |

— | ✓ |

|

Lathe with Y axis support

|

— | ✓ |

Custom Stock Profile

Custom Stock ProfileDefine a custom revolved stock profile for turning; toolpaths outside the stock are automatically trimmed. You can also select the profile area to machine directly from the operation—ideal for pre-machined blanks.

|

— | ✓ |

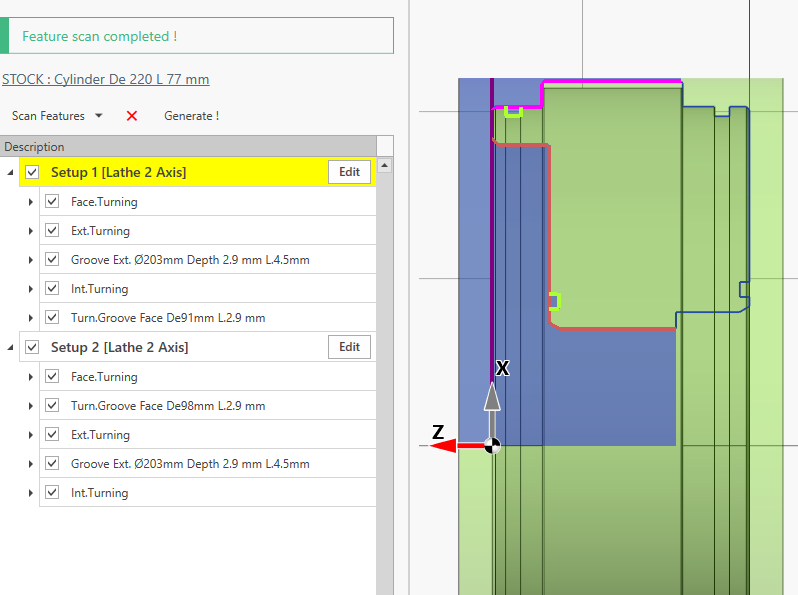

Turning Feature Recognition

Turning Feature RecognitionAutomatically recognize turning features from a 3D model and convert them into turning operations. Ideal for fast quoting and quick project setup.

|

— | ✓ |

Try the full software with no feature limits during your trial period.

This is a relatively new software . Thanks to users feedback it's becoming more stable. But new bugs can be created at every release.

Every machine can interpreter the same g-code in different way.

You need to understand clearly the meaning of the generate g-code and your responsibility check the compatibilty with your machine.

Make some dry-run test before start cutting real material, check the generate g-code step by step.

Everything you need to know about eCam CNC software

Created by a machinist, for machinists

Developed by Alessandro Cogo with 20+ years of hands-on CNC programming experience. Built by someone who's been in your shoes, working daily with lathes, mills, and quotation systems in real manufacturing environments.

Over 1000 licenses sold worldwide since 2015. Continuously improved based on real user feedback from professional workshops.

No hidden fees, no subscriptions. Lifetime licenses with clear pricing. Free demo available to try before you buy.

Extensive documentation at docs.e-cam.it with tutorials, guides, and examples. Regular updated.

Machinist-Built CNC Programming Software

eCam was developed by Alessandro Cogo, a CNC programming expert with over 20 years of hands-on experience working directly with lathes, mills, and quotation systems in manufacturing environments.

Born from the need to simplify G-code generation for machinists, eCam combines deep technical expertise in CNC operations with intuitive software design. Since the first commercial release in 2015, eCam has been helping manufacturers worldwide streamline their CNC programming workflow.

Send files and questions to customer support

Alternatively, send an email to the address shown at the bottom of the page.